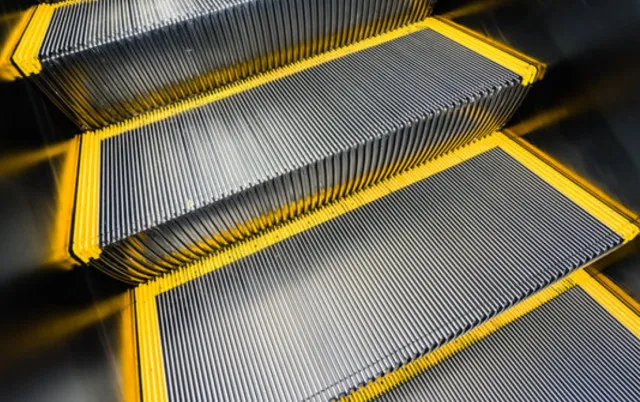

Escalators are a part of our daily lives, seamlessly transporting us through shopping malls, airports, and train stations. They’re so common that we often overlook their design. But have you ever noticed the grooves on the escalator steps and wondered what they’re for? It turns out, those grooves aren’t just there for show—they’re a vital part of the escalator’s safety and functionality.

The Primary Purpose of Escalator Grooves

At first glance, you might think the grooves are there to prevent slipping. While they do improve traction, their primary purpose lies in their interaction with a key safety feature called the comb plate.

As escalator steps move, they reach the top or bottom where they slide into a comb-like plate. The grooves align perfectly with this plate, ensuring a smooth transition between the moving steps and the stationary floor. This design prevents objects like bags, clothing, or debris from getting trapped between the steps and the floor—a potential hazard that could cause the escalator to malfunction or result in accidents.

Without the grooves, items could easily snag in the gaps, creating dangerous situations. By fitting snugly into the comb plate, the grooves act as a barrier against such risks, making escalators safer for everyone.

Preventing Debris Buildup

Escalator grooves also serve a secondary but equally important purpose: keeping the steps clean. Escalators encounter a lot of foot traffic, and with it comes dirt, liquids, and small debris. The grooves help channel these contaminants into the spaces between the steps, preventing them from building up on the surface where passengers stand.

For example, if someone spills a drink, the liquid can collect in the grooves, reducing the risk of creating a slippery surface. This simple yet effective design keeps the escalator operational and ensures that passengers remain safe from slipping accidents.

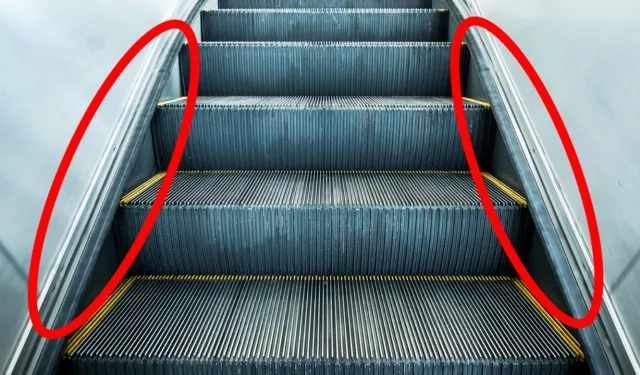

How Safety Brushes Work Alongside Grooves

You’ve probably noticed the small brushes lining the edges of escalators. While they might seem like a cleaning tool, their real purpose is safety.

These safety brushes are designed to prevent items like shoelaces, clothing, or bags from getting caught between the escalator steps and the side panels, known as skirts. Their role is twofold:

- Physical Barrier: The brushes act as a buffer, physically keeping loose items away from the dangerous gap between the steps and the skirt.

- Psychological Cue: If you feel the brush against your leg or bag, your instinct is to move away. This subconscious reaction keeps passengers and their belongings out of harm’s way.

Safety brushes became mandatory in 2004 under British and European standards, underscoring their importance in modern escalator design.

The Role of Grooves in Passenger Safety

The grooves and safety brushes work together as part of a broader system to protect passengers. Here are some specific ways they contribute to safety:

- Preventing Snags: Grooves align with the comb plate to stop items from getting stuck at the transition points.

- Reducing Slips: By channeling liquids and debris, grooves maintain a cleaner, less slippery surface for passengers.

- Protecting Clothing and Accessories: Brushes keep loose items away from moving parts, preventing entanglement.

Each of these features may seem minor, but together they create a robust safety system that allows escalators to operate smoothly and safely.

Why These Features Matter

Escalators transport millions of people every day, and their reliability is crucial. Without thoughtful safety features like grooves and brushes, escalators would pose significant risks. For example:

- Items getting stuck in the mechanism could cause the escalator to stop abruptly, potentially leading to injuries or malfunctions.

- Without grooves, slippery surfaces could increase the likelihood of passengers falling.

- Loose clothing caught in the side gaps could lead to serious accidents, especially for children or people wearing long garments.

These seemingly small design elements help avoid such dangers, keeping passengers safe and ensuring escalators run efficiently.

The Engineering Behind Escalator Grooves

The design of escalators is far from simple. Every element, from the grooves to the comb plates, is meticulously engineered to provide a seamless experience. Grooves must be deep enough to align with the comb plate but not so deep that they compromise the strength of the steps. Materials used for the steps and grooves are also carefully chosen to withstand wear and tear from constant use.

This attention to detail is what makes escalators both safe and reliable, even with the heavy traffic they endure daily.

Taking Escalator Safety for Granted

It’s easy to overlook the intricate design of escalators when we use them so casually. However, every feature, no matter how small, plays a vital role in keeping us safe. The grooves and safety brushes might not stand out, but they’re essential to the escalator’s operation.

The next time you step onto an escalator, take a closer look. Notice how the grooves fit perfectly into the comb plate, how the brushes gently nudge your bag away from the edges, and how smooth the ride feels. These features are a testament to the brilliance of modern engineering.

Conclusion: The Hidden Genius in Everyday Design

Escalators are more than just a convenient way to move between floors—they’re a marvel of engineering designed with passenger safety in mind. The grooves on the steps might seem like a small detail, but they serve a critical purpose: preventing debris buildup, improving traction, and ensuring a safe transition between moving and stationary parts. Paired with safety brushes, they form a reliable system that protects millions of passengers every day.

So, the next time you’re riding an escalator, remember the ingenuity behind those grooves. It’s a reminder that even the smallest design elements can have the biggest impact on our safety and convenience.