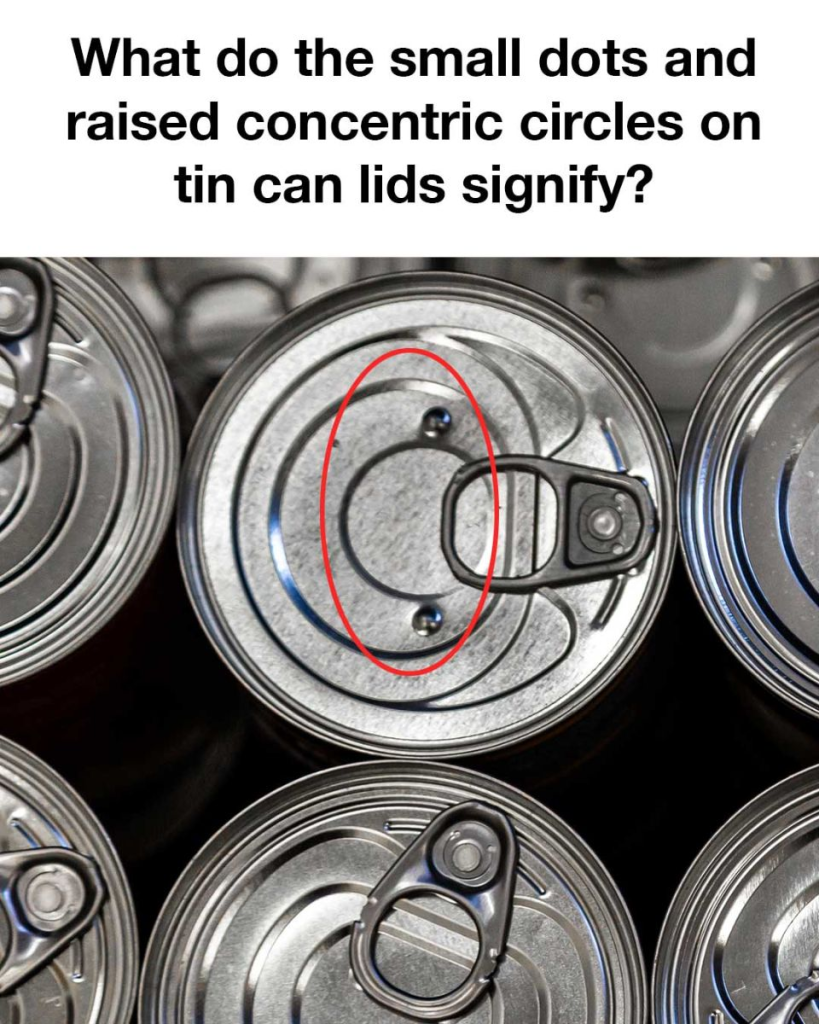

Ever noticed those tiny dots stamped into the lid of a tin can? They’re easy to overlook—but they’re not just there for decoration. These little marks are actually part of a highly precise system that makes modern food packaging safe, efficient, and reliable.

In the world of mass production, machines need visual or tactile cues to align lids properly. These dots act as reference points, allowing canning machines to center, seal, and rotate the lid with precision. Think of them as tiny road signs for factory robots—guiding lids into perfect position during the sealing process. Miss that alignment, and you risk an unsealed can or spoiled food. No thank you.

And here’s another cool thing: those dots often help in quality control. If something goes wrong during packaging, manufacturers can trace the issue back to the exact spot—or even the machine—that created the defect, all thanks to these tiny identifiers.

What’s Up With the Circles? Understanding Raised Rings on Can Lids

Now let’s talk about those raised concentric circles. You’ve probably felt them while opening a can or maybe seen them glint under the kitchen light. They might look like a design choice, but they’re actually functional on multiple levels.

First off, these circles add strength. Imagine pushing the lid of a can during processing—without those ridges, it might bend or pop. But with the reinforced rings? The lid stays firm under pressure. It’s like the steel beams inside a skyscraper—they keep everything from collapsing.

Secondly, they help consumers. Ever used a manual can opener and wondered where to start? Those circles serve as a tactile guide, making it easy to position the blade in the right spot for a clean, smooth cut. No guesswork, no mess.

A Little History: How These Design Elements Evolved

Video: the secrets behind those little dots and concentric circles on tin can lids

The concept of canning dates back to the early 1800s, but back then, cans were clunky, hard to open, and prone to failure. As demand for long-lasting food storage grew, so did innovation.

Engineers and manufacturers realized that even tiny details—like how a lid is shaped or marked—could make a huge difference in how well the product held up during transit, storage, and use. So those dots and circles? They were born out of trial, error, and clever problem-solving.

In fact, over the decades, the lid design has been fine-tuned to balance efficiency, safety, and ease of use. And today’s tin can lid is the result of years of mechanical refinement and human-centered design.

Smooth Manufacturing: How Dots Prevent Snags on the Production Line

Modern canning machines move fast—really fast. We’re talking hundreds of cans per minute. Any snag in that system can bring the entire production line to a halt.

Those tiny bumps on the lid reduce friction and help guide the can smoothly through conveyor belts and sealing stations. It’s a bit like adding grooves to a racetrack to keep the cars from skidding off course. Less friction equals fewer jams, which equals fewer headaches for factory workers and less waste overall.

Aligning the Lid for an Airtight Seal

Here’s where precision becomes absolutely critical. If the lid isn’t aligned just right, the vacuum seal might fail. That means air, bacteria, and contaminants could slip in—and nobody wants that surprise when opening a can of soup.

The dots on the lid help align it exactly as needed during the sealing process. Some machines use laser scanners or mechanical feelers to detect those marks and position the lid to the millimeter. Once it’s perfectly placed, the machine creates an airtight vacuum seal. Result? Fresh, safe food that can sit on a shelf for years without spoiling.

Creases That Actually Help You Open the Can

Video: How to REMOVE Tops From Aluminum Cans – 3 Different Ways

You know those ridged rings we talked about? They aren’t just structural—they’re also practical for the user. Those raised lines help your can opener grip the metal and cut evenly. It’s like pre-marking the dotted line before you cut with scissors.

Without those guides, the blade of the opener might slip or require more force. The ridges reduce resistance, making the cutting action smoother and safer. It’s a small touch that makes a big difference—especially when you’re in a rush and just want to get dinner on the table.

Why This Matters: Design That Impacts Our Everyday Lives

We often think of packaging as something to throw away. But the reality? The design of a can lid affects not just your cooking routine, but also food safety, waste reduction, and industrial efficiency.

The small dots and raised circles are silent heroes. They help machines function flawlessly, reduce spoilage, and make your experience as a consumer more intuitive. This is engineering at its best—solving big problems with subtle solutions.

Conclusion: The Genius Hidden in Plain Sight

So next time you grab a can of beans or soup, take a second to look at the lid. Those tiny dots and concentric rings aren’t just random—they’re the result of years of innovation designed to make your life easier and your food safer. What seems like a simple circle of metal is actually a finely tuned tool of modern food preservation.