Before push-to-connect fittings and prefab parts ruled the world of plumbing and automotive repairs, there was a simple tool that quietly carried entire systems on its back—the vintage flaring tool.

This humble yet ingenious piece of metalwork wasn’t just a gadget tossed in a toolbox. It was an essential. If you grew up around mechanics, repair shops, or home fix-it pros, chances are you’ve seen one up close—or even used it yourself. If you remember it, you probably already know: this little tool meant business.

The Birth of a Workbench Legend

The vintage flaring tool first found its footing during the late 1800s and early 1900s, when industry was booming and infrastructure was evolving at lightning speed. Tubes and pipes were everywhere—in homes, cars, factories—and they all needed to be connected tightly, safely, and permanently.

And that’s where this tool stepped in.

Its job? To flare the ends of metal tubes—spreading them into a funnel shape—so that when you clamped two pieces together, you had a leak-proof, pressure-resistant connection. In short, it was the difference between a working gas line and a dangerous one.

Video: How to use a Flaring Tool – Double Flare

How It Worked: Simple, Tough, Brilliant

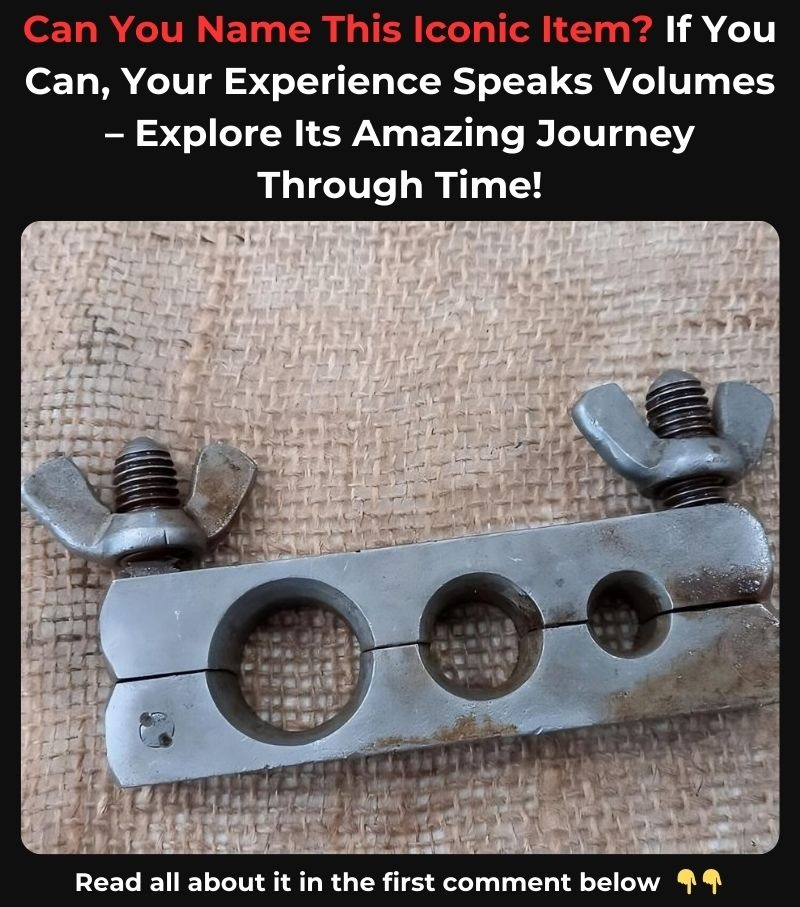

At first glance, the vintage flaring tool might look like a cross between a clamp and a crank. But this was no gimmick. It had a solid steel frame, wing nuts for tightening, and a conical press that shaped the tubing just right.

You’d start by inserting a section of soft metal tubing—like copper or aluminum—into the tool’s die block. Once secured, you’d tighten down the cone into the end of the tube, flaring it out perfectly.

This flare wasn’t just for looks. It created a compression fit so tight it could withstand water, gas, fuel—even brake fluid under pressure.

No batteries. No wires. Just physics, friction, and steel. The kind of engineering that’s so good, it never goes out of style.

Why It Was a Lifesaver in So Many Fields

What made the vintage flaring tool truly iconic wasn’t just its function—it was its versatility. This wasn’t a one-job pony. It showed up across industries and always pulled its weight.

In the garage: Mechanics used it religiously to repair fuel lines, brake systems, and air conditioning units. For anyone restoring classic cars, this tool was—and still is—a must-have.

In the house: Plumbers used it to seal copper water lines and gas pipes. Especially in rural areas, where calling a professional was a luxury, homeowners often had one on hand for DIY repairs.

In industry: From refrigerators to airplanes, any system that moved liquid or gas through tubes likely involved a flaring tool. Its role in early aviation, HVAC systems, and even wartime machinery can’t be overstated.

A Snapshot of Craftsmanship: Tools That Were Built to Last

Here’s what sets vintage flaring tools apart from most modern gear: they weren’t made to be replaced. They were made to last.

Crafted from tough-as-nails metals—like cast iron or hardened steel—these tools didn’t just survive decades of use; they thrived in them. It wasn’t unusual for a flaring tool to be passed down through generations, still fully functional.

There were no plastic handles or breakable parts. Everything had a purpose. And that kind of build quality made the tool not just useful—but meaningful.

Flaring Tools and World War II: Unsung Military MVPs

Want to know how important these tools were? During WWII, they were essential in building everything from tanks to bombers. Soldiers and engineers in the field needed compact, reliable tools to make fast, leak-free connections under pressure. The flaring tool delivered.

Without this little workhorse, critical systems like fuel lines and hydraulics could’ve failed. That’s not just impressive—it’s heroic.

From Workbench to Display Shelf: A Collector’s Treasure

Today, vintage flaring tools are enjoying a well-earned retirement. But don’t be fooled—they still work just as well as they did back in the day.

Collectors now hunt them down in antique shops, flea markets, and estate sales. Some are restored and used in classic car garages. Others sit proudly on display, their steel bodies a tribute to a time when tools didn’t just do the job—they defined it.

Early models, especially those with unique engravings or original wooden handles, are particularly prized. They tell stories—not just of tasks completed, but of an era when self-reliance wasn’t trendy. It was necessary.

Why This Icon Still Resonates Today

Video: 105 YEARS Old Transforming a Rusted Vintage Flaring Tool: A Restoration Revival

So, why does the vintage flaring tool still matter in our high-tech world?

Because it symbolizes more than just manual labor. It’s a reminder of how clever design, honest materials, and hands-on skill can still beat out flashy features and throwaway culture.

It represents pride in doing the job right—the first time. It’s about rolling up your sleeves, figuring it out, and making something work with what you have. No YouTube tutorial needed. Just knowledge, intuition, and a tool that won’t let you down.

Conclusion: A Legacy Forged in Steel

The vintage flaring tool may not get much attention in today’s world of cordless gadgets and push-button everything—but it absolutely deserves our respect.

It shaped industries, supported war efforts, saved countless households from calling the plumber, and introduced generations to the value of hard work and precision. It’s more than just a tool—it’s a symbol of an era that valued function, durability, and craftsmanship.

So next time you spot one in a garage sale or tucked away in your grandpa’s toolbox, don’t overlook it. That hunk of steel might just be one of the greatest unsung heroes of practical invention.

Because when you can name it, you don’t just remember it—you honor everything it stood for