Sausage-making has been a beloved culinary tradition for centuries, tracing its origins to ancient Greece and Rome. This art involves a delicate mix of spices, meats, and herbs, all neatly packed into casings, resulting in delicious, flavorful sausages. Traditionally, this was a labor-intensive process carried out by skilled butchers. However, with advances in technology, sausage production has undergone a remarkable transformation. Enter the sausage-making machine—a game-changing device that has redefined the process, making it faster, more efficient, and consistent.

The Early Days of Sausage-Making: Hand-Stuffing to Early Mechanization

In the beginning, making sausages was entirely manual, involving hand-stuffing casings with seasoned meat mixtures. This process required time, effort, and skill, making sausage production a demanding task. Butchers often made small batches, limiting how quickly they could meet demand.

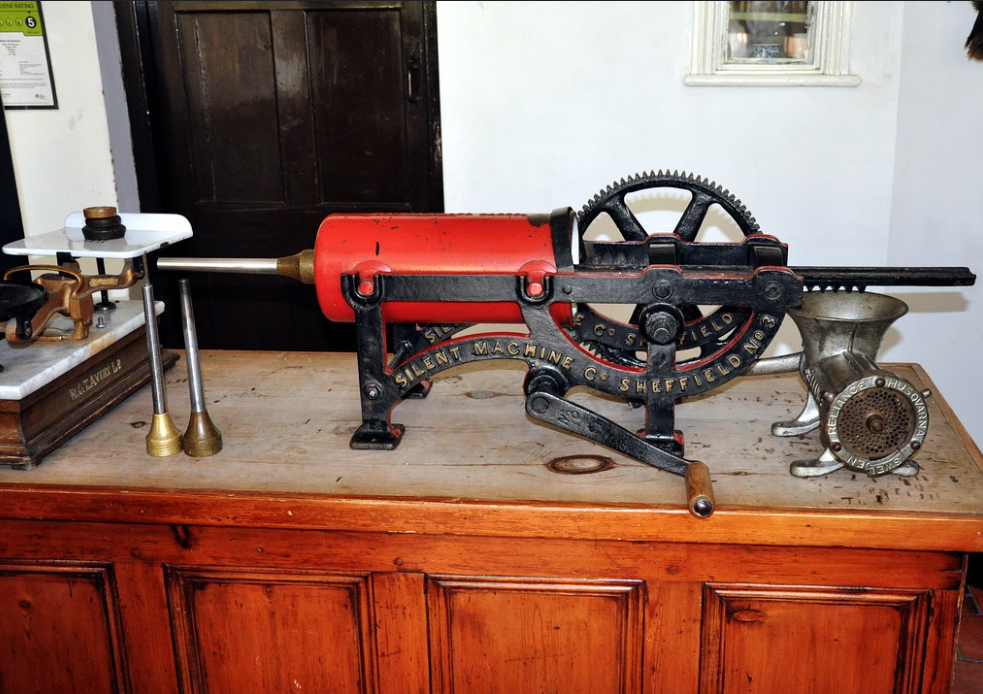

The 19th century ushered in a wave of industrialization, sparking the need for more efficient meat processing methods. Early sausage-making machines emerged as a response, primarily as hand-cranked devices that allowed butchers to fill casings faster than manual methods. These rudimentary machines set the foundation for more advanced, mechanized models that would later revolutionize sausage production.

Technological Advancements in Sausage-Making Machines

As technology evolved, so did the capabilities of sausage-making machines. By the early 20th century, steam-powered machines entered the scene, significantly increasing production rates. These machines featured a piston mechanism that pushed meat mixtures into casings, making the process faster and reducing labor costs.

The advent of electricity brought a new era of sausage production. Electric-powered machines offered consistent output, improved safety, and increased reliability. These machines could handle larger quantities of meat, making them ideal for both small butcheries and large-scale processing plants. Key features of modern machines include:

- Adjustable Fill Speed: Operators can control the speed of filling, achieving optimal results based on the type of sausage.

- Automatic Casing Control: This reduces the risk of bursting casings during the filling process, ensuring a uniform product.

- Hygienic Design: Easy-to-clean components enhance food safety, helping manufacturers comply with strict safety standards.

How Sausage-Making Machines Transformed the Meat Industry

The introduction of sausage-making machines marked a significant shift in the meat industry. By automating the production process, these machines offered several advantages:

- Increased Efficiency: Machines can produce sausages at a much faster rate than manual methods, enabling manufacturers to meet rising consumer demand.

- Consistent Quality: The use of machines ensures uniform size, shape, and filling, which is crucial for maintaining consistent product quality.

- Reduced Labor Costs: Mechanization reduces the need for manual labor, cutting costs and boosting profitability for sausage manufacturers.

The enhanced production capabilities of sausage-making machines have also led to more innovation in sausage varieties. With greater capacity, manufacturers have the freedom to experiment with new flavors, spices, and ingredients, resulting in a broader selection of sausages for consumers.

Exploring Different Types of Sausage-Making Machines

Sausage-making machines come in a variety of designs, each catering to different production needs. Let’s take a look at the most common types:

- Manual Sausage Fillers: These hand-cranked machines are perfect for small-scale production or home use. They are ideal for hobbyists or small butcheries that produce limited batches.

- Electric Sausage Stuffers: Using an electric motor, these machines offer consistent output, making them suitable for medium-sized butcheries and restaurants. They streamline production while maintaining quality.

- Hydraulic Sausage Fillers: These machines operate at high speeds, making them suitable for larger butcheries and processing plants. They offer adjustable pressure settings, making it possible to produce different types of sausages, from fine bratwursts to coarse Italian sausages.

- Vacuum Sausage Fillers: These advanced machines use a vacuum system to remove excess air from the meat mixture before it enters the casing. This ensures a tighter fill and extends the sausage’s shelf life. Vacuum fillers are commonly found in large-scale meat processing facilities.

- Fully Automated Sausage-Making Lines: Designed for industrial use, these machines handle every step of the process, from grinding and mixing meat to filling, linking, and packaging sausages. Capable of producing thousands of sausages per hour, they meet the demands of mass production.

Safety and Hygiene in Modern Sausage-Making

As food safety standards have become more rigorous, manufacturers have focused on improving hygiene and safety in sausage-making machines. These machines now feature designs that minimize contamination risks, ensuring safe, high-quality sausages.

- Stainless Steel Construction: Most machines are made of stainless steel, a non-corrosive, easy-to-clean material suitable for food production.

- Removable Parts: Detachable components allow for thorough cleaning and sanitation, reducing the risk of contamination.

- Protective Shields: Safety shields and automatic shut-off features prevent accidents, protecting operators during the production process.

These advancements not only improve product safety but also ensure compliance with increasingly stringent food safety regulations.

The Role of Sausage-Making Machines in Today’s Culinary Landscape

Sausage-making machines have become indispensable in both commercial and artisanal production. From traditional butcheries to large-scale meat processing plants, these machines ensure efficiency, quality, and consistency. They also play a crucial role in the growing trend of craft sausages, enabling artisanal producers to experiment with local ingredients, spices, and innovative recipes.

By streamlining production while preserving the integrity of flavors, sausage-making machines have helped bring more unique and diverse options to the market. Whether it’s a spicy chorizo, a savory bratwurst, or a herb-infused Italian sausage, the possibilities are nearly endless.

Conclusion: The Future of Sausage-Making Machines

Sausage-making machines have come a long way since their inception, evolving from simple hand-cranked devices to fully automated systems capable of producing thousands of sausages in a day. These machines have not only transformed the meat industry but also bridged the gap between tradition and modernity. With ongoing advancements in automation, hygiene, and safety, the future of sausage production looks promising.

As consumer demand for quality and variety continues to rise, sausage-making machines will remain at the forefront of culinary innovation. Whether you’re a butcher, chef, or home cook, these machines blend heritage with technology, making sausage production faster, safer, and more enjoyable.